This post originally appeared on the City of Auburn News.

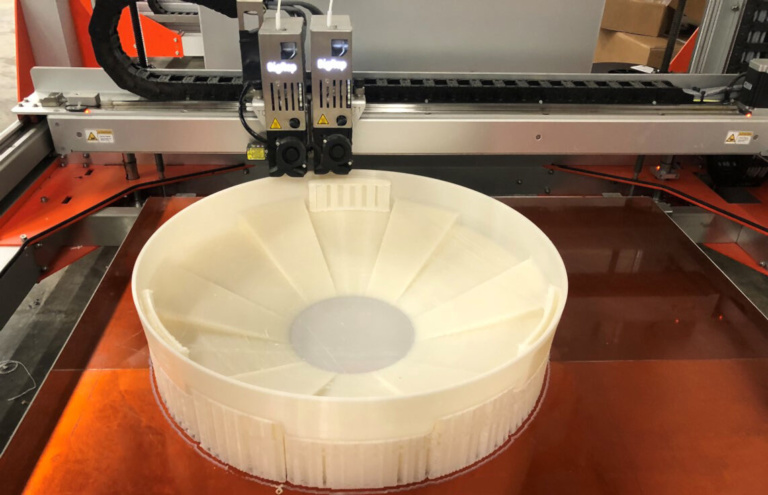

Alabama manufacturers and entrepreneurs now have a new resource to help further their innovation, the Additive Manufacturing Accelerator (AMA) in Auburn.

The accelerator was established to aid industries and startups as they create and develop new products using advanced additive methods, or 3D printing, in metals and polymers. Participants in the program receive engineering and business consulting, access to robust additive machines and a finished prototype of their product.

The AMA was developed through a partnership among the National Center for Additive Manufacturing Excellence, Auburn University’s Samuel Ginn College of Engineering and Harbert College of Business, Auburn Training Connection, Auburn manufacturing company SWIGRO and the City of Auburn.

“We are excited to partner with Alabama industries as they look for ways to incorporate the latest advances in additive manufacturing technology,” said Chris Roberts, dean of the Auburn University Samuel Ginn College of Engineering. “It is our intention to apply the research and technology development from our laboratories to make a real difference in our state’s manufacturing sector. We also benefit by hearing directly from industries to strategically inform our research and education programs.”

Current program participants include a diverse representation of industry, including manufacturers in the aerospace, automotive and tooling sectors along with startups in consumer goods. One example is Hartzell Engine Technologies, a manufacturer in Montgomery that produces general and military aircraft engine accessories and cabin heating solutions.

“Additive was something that we at Hartzell had wanted to pursue but never had the dedicated resources, which was only compounded by COVID,” said Judd Hough, Hartzell’s director of engineering. “This accelerator provides the perfect opportunity for us to take advantage of outside additive expertise and funds for machine time to investigate this technology and its possible applications to improve our business.”

Local startup XO Armor has also benefitted from the accelerator. The company produces highly customized protective gear for use in sports and beyond. Through the AMA, they’ve connected with LaKami Baker, associate professor of management at the Harbert College of Business, who has provided one-on-one coaching to improve XO Armor’s business planning and development.

“If it weren’t for AMA, we wouldn’t have been able to get a jump on our business development guided by Dr. Baker,” said Dr. Michael Zabala, co-founder of XO Armor. “We have also been able to learn more about available print options and to produce multiple prototypes, which we then submit to rigorous mechanical integrity testing in order to improve our end product.”

The Additive Manufacturing Accelerator is partly funded by the Alabama Research Alliance and Alabama Department of Economic and Community Affairs. It is sponsored by Auburn Training Connection and the City of Auburn.

“The accelerator represents an innovative collaboration between industry, academia and government,” said Auburn Mayor Ron Anders. “Alabama’s reputation is advancing as a leader in additive manufacturing. By leveraging and connecting the many assets our region has to offer, we have the power to drive further progress. I applaud the City of Auburn’s Economic Development Department, the College of Engineering and all involved for their role in this technology initiative. The partners assembled make this special program possible and impactful.”

For more information about the accelerator, visit auburnalabama.org/am-accelerator or call 334-501-7377.